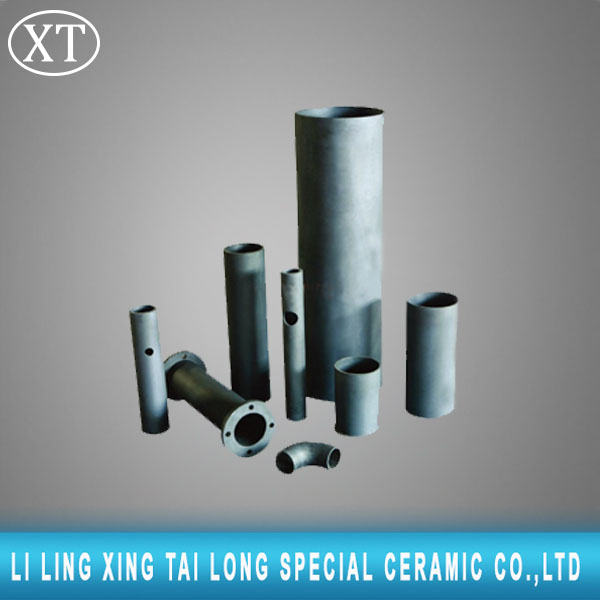

Product Description

SiC Burner Tubes

1. High temperature tolerance

2. Oxidation resistance

3. Wear resistance

4. Corrosion resistance

RBSiC (SiSiC) Burner Tubes have superior rapid cooling and rapid heating resistance, wear resistance,

oxidation resistance, high bending strength, no falling slag, no crazing, have a long time service life,

easy to change, effective to control the uniform temperature inside the kilns.

RBSiC (SiSiC) Burner Tubes are widely used in shuttle kilns, tunnel kilns, roller kilns and other fuel

industry kilns.

Technical Parameter of Reaction Bonded Silicon Carbide

|

item |

unit |

data |

|

temperature of application |

C |

1380 |

|

density |

g/cm3 |

>=3.02 |

|

open porosity |

% |

<0.1 |

|

bending strength |

Mpa |

250(20C) |

|

|

Mpa |

280(1200C) |

|

modulus of elasticity |

Gpa |

330(20C) |

|

|

Gpa |

300(1200C) |

|

thermal conductivity |

W/m.k |

45(1200C) |

|

coefficient of thermal expansion |

K-1*10-6 |

4.5 |

|

rigidity |

|

13 |

|

acid-proof alkaline |

|

Excellent |

Our Services

1.Why choose Xingtailong?

High puriy material make sure high max working temperature,

Tight tolerance make sure the right installation.

Large quantity in stock ensured fast delivery.

Large capacity reduce materical prices.

2.Our service of Xingtailong:

Inquiry response: Your inquiries will be replied in 24 hours.

Sample support: Two free samples are available in 3~5days.

Delivery time: Your shipment will be loaded in 15~25days.depends on quantity.

Payment term: T/T, L/C, D/P, D/A, Western Union (Sample only) We can supply the products according to customer's